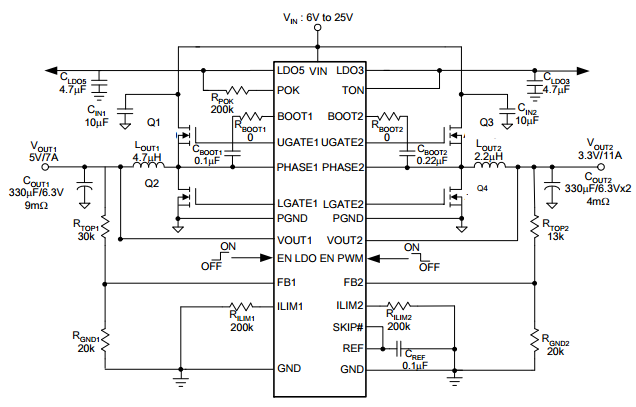

CXSD62104集成了双降压、恒定时间、同步PWM控制器(为每个通道驱动双N通道mosfet)和

两个低损耗稳压器以及各种保护装置集成到一个芯片中。PWM控制器降低电池的高电压以产生NB的低电压应用。PWM1和PWM2的输出可以从2V调整到5.5V通过设置一个从VOUTx到GND的电阻分压器。线性调节器为备用电源提供5V和3.3V输出

-

[ 产品资料下载 ]

|

目录 1.产品概述 2.产品特点 一,产品概述(General Description) The CXSD62104 integrates dual step-down, constant-ontime, synchronous PWM controllers (that drives dual N-channel MOSFETs for each channel) and provide up to 100mA output current. When the PWMx output voltage is higher than LDOx bypass threshold, the related LDOx regulator is shut off and its output is connected to VOUTx by internal switchover MOSFET. It can save power dissipation. output voltage in either PFM or PWM Mode.In Pulse-Frequency Mode (PFM), the CXSD62104 provides very high efficiency over light to heavy loads with loading-modulated switching frequencies. The Forced-PWM mode works nearly at constant frequency for low-noise requirements. The unique ultrasonic mode maintains the switching frequency above 25KHz, which eliminates noise in audio applications. The CXSD62104 is equipped with accurate sourcing cur-rent-limit, output under-voltage and output over-voltage protections, being perfect for NB applications. A 1.7ms (typ.) digital soft-start can reduce the start-up current. A soft-stop function actively discharges the output capaci-tors by the discharge device. The CXSD62104 has individual enable controls for PWM channels and LDOs. Pulling both ENPWM pin and ENLDO pin low shuts down the whole chip with low quiescent current close to zero. 70% Under-Voltage and 125% Over-Voltage Protec-tions (PWM) Adjustable Current-Limit Protection (PWMs) 三,应用范围 (Applications) Notebook and Sub-Notebook Computers Portable Devices 四.下载产品资料PDF文档 |

需要详细的PDF规格书请扫一扫微信联系我们,还可以获得免费样品以及技术支持!

五,产品封装图 (Package)

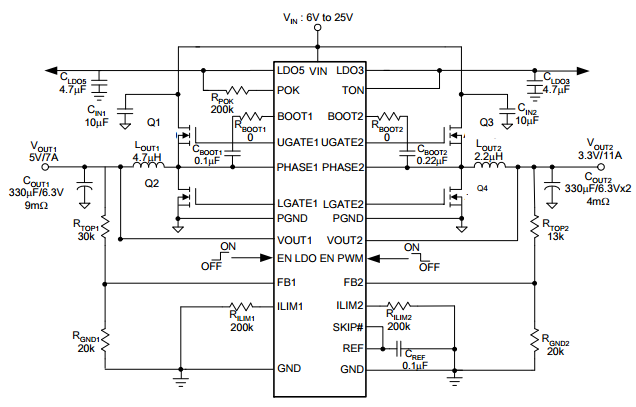

六.电路原理图

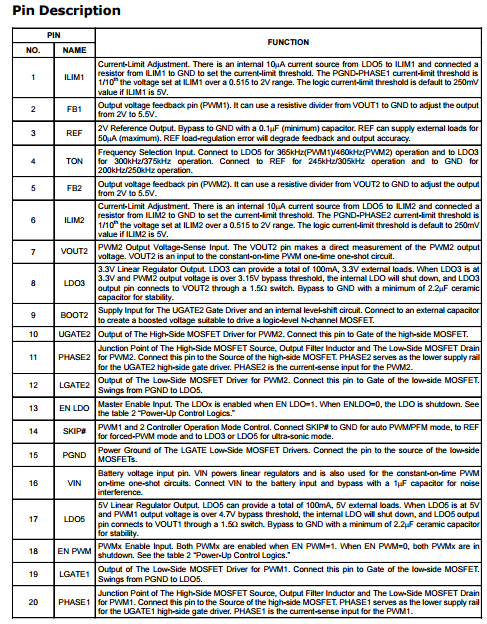

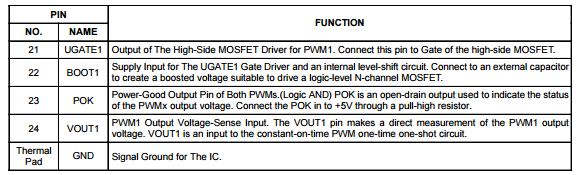

七,功能概述

Input Capacitor Selection

The input capacitor is chosen based on the voltage rating and the RMS current rating. For reliable operation, select

the capacitor voltage rating to be at least 1.3 times higher than the maximum input voltage. The maximum RMS

current rating requirement is approximately IOUT/2, where IOUT is the load current. During power up, the input capaci-tors have to handle large amount of surge current. In low-duty notebook appliactions, ceramic capacitors are

remmended. The capacitors must be connected between the drain of high-side MOSFET and the source of low-

side MOSFET with very low-impeadance PCB layout.

MOSFET Selection

The application for a notebook battery with a maximum volt-age of 24V, at least a minimum 30V MOSFETs should

be used. The design has to trade off the gate charge with the RDS(ON) of the MOSFET:

· For the low-side MOSFET, before it is turned on, the body diode has been conducted. The low-side MOSFET

driver will not charge the miller capacitor of this MOSFET.

In the turning off process of the low-side MOSFET,the load current will shift to the body diode first. The

high dv/dt of the phase node voltage will charge the miller capacitor through the low-side MOSFET driver

sinking current path. This results in much less switching loss of the low-side MOSFETs. The duty

cycle is often very small in high battery voltage applications, and the low-side MOSFET will con-

duct most of the switching cycle; therefore, the less the RDS(ON) of the low-side MOSFET, the less the power

loss. The gate charge for this MOSFET is usually a secondary consideration. The high-side MOSFET

does not have this zero voltage switching condition, and because it conducts for less time

compared to the low-side MOSFET, the switching loss tends to be dominant. Priority should be given

to the MOSFETs with less gate charge, so that both the gate driver loss and switching loss will be minimized.

The selection of the N-channel power MOSFETs are de-termined by the RDS(ON), reversing transfer capacitance

(CRSS) and maximum output current requirement. The losses in the MOSFETs have two components: conduc-

tion loss and transition loss. For the high-side and low-side MOSFETs, the losses are approximately given by

the following equations:

Layout Consideration

In any high switching frequency converter, a correct layout is important to ensure proper operation of the regulator.

With power devices switching at higher frequency, the resulting current transient will cause voltage spike across

the interconnecting impedance and parasitic circuit elements. As an example, consider the turn-off transition

of the PWM MOSFET. Before turn-off condition, the MOSFET is carrying the full load current. During turn-off,

current stops flowing in the MOSFET and is freewheeling by the lower MOSFET and parasitic diode. Any parasitic

inductance of the circuit generates a large voltage spike during the switching interval. In general, using short and

wide printed circuit traces should minimize interconnect-ing impedances and the magnitude of voltage spike. And

signal and power grounds are to be kept separating and finally combined to use the ground plane construction or

single point grounding. The best tie-point between the signal ground and the power ground is at the negative

side of the output capacitor on each channel, where there is less noise. Noisy traces beneath the IC are not

recommended. Below is a checklist for your layout:

Layout Consideration (Cont.)

Keep the switching nodes (UGATEx, LGATEx, BOOTx,and PHASEx) away from sensitive small signal nodes

(REF, ILIMx, and FBx) since these nodes are fast mov-ing signals. Therefore, keep traces to these nodes as

short as possible and there should be no other weak signal traces in parallel with theses traces on any layer.

Minimizing the impedance with wide layout plane be-tween the two pads reduces the voltage bounce of

八,相关产品 更多同类产品......

|

Switching Regulator > Buck Controller |

||||||||||

|

Part_No |

Package |

Archi tectu |

Phase |

No.of PWM Output |

Output Current (A) |

Input Voltage (V) |

Reference Voltage (V) |

Bias Voltage (V) |

Quiescent Current (uA) |

|

|

min |

max |

|||||||||

|

SOP-14 QSOP-16 QFN4x4-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

8000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP8|TSSOP8 |

VM |

1 |

1 |

5 |

5 |

13.2 |

1.25|0.8 |

5~12 |

3000 |

|

|

SOP-8 |

VM |

1 |

1 |

10 |

3.3 |

5.5 |

0.8 |

5 |

2100 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

2000 |

|

|

TSSOP-24 |QFN5x5-32 |

VM |

1 |

2 |

20 |

5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP14 QSOP16 QFN-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

4000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

25 |

2.2 |

13.2 |

0.8 |

12 |

5000 |

|

|

LQFP7x7 48 TQFN7x7-48 |

VM |

1 |

6 |

0.015 |

1.4 |

6.5 |

- |

5 |

1800 |

|

|

TSSOP-24P |

VM |

1 |

2 |

20 |

2.97 |

5.5 |

0.8 |

5~12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

3000 |

|

|

SOP-8-P|DIP-8 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

1.2 |

12 |

3000 |

|

|

SSOP28 QFN4x4-24 |

VM |

1 |

2 |

20 |

5 |

24 |

0.9 |

5 |

1200 |

|

|

SOP-20 |

VM |

1 |

2 |

20 |

2.2 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8|DFN3x3-10 |

VM |

1 |

2 |

- |

- |

- |

- |

5~12 |

550 |

|

|

DIP8|SOP-8 |

VM |

1 |

1 |

1 |

1.2 |

9 |

24 |

5 |

9 ~ 24 |

|

|

SSOP16 QFN4x4-16 TQFN3x3-16 |

VM |

1 |

1 |

25 |

3 |

25 |

0.6 |

5 |

1700 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

3 |

25 |

0.5 |

5 |

350 |

|

|

QFN4x4-24 |

CM |

2 |

1 |

40 |

4.5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8P TDFN3x3-10 |

VM |

1 |

1 |

20 |

3 |

13.2 |

0.8 |

5~12 |

2500 |

|

|

SOP8P |

VM |

1 |

1 |

25 |

3 |

13.2 |

0.6|0.8 |

5~12 |

1200 |

|

|

TDFN3x3-10 |

VM |

1 |

1 |

25 |

4 |

13.2 |

0.8 |

5~12 |

2000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

4.5 |

25 |

0.6 |

5~12 |

80 |

|

|

SOP-8P |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.8 |

5~12 |

16000 |

|

|

TQFN3x3-10 |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.6 |

5~12 |

2500 |

|

|

CXSD62101|L |

TDFN3x3-10 |

COT |

1 |

1 |

30 |

3 |

25 |

0.8 |

5~12 |

2000 |

|

TQFN3x3-16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

|

CXSD62102A |

TQFN 3x3 16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

QFN4x4-24 |

VM |

2 |

1 |

50 |

4.5 |

13.2 |

0.6 |

5~12 |

5000 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

CXSD62106|A |

TQFN4x4-4 TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

800 |

|

TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3.5x3.5-14 TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

TQFN3x3-16 |

COT |

1 |

2 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3x3-20 TQFN3x3-16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5|0.5 |

5 |

740 |

|

|

TQFN4x4-24 |QFN3x3-20 |

CM |

1 |

2 |

15 |

5 |

28 |

0.5 |

N |

3000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.5 |

5 |

250 |

|

|

CXSD62113|C |

TQFN3x3-20 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

CXSD62113E |

TQFN 3x3 20 |

COT |

2 |

2 |

11 |

6 |

25 |

2 |

N |

550 |

|

TQFN3x3-20 |

COT |

2 |

2 |

11 |

5.5 |

25 |

2 |

N |

280 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.85 |

12 |

5000 |

|

|

CXSD62116A|B|C |

SOP-8P |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

16000 |

|

SOP-20 |

VM |

2 |

2 |

30 |

10 |

13.2 |

1 |

12 |

5000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

1.8 |

28 |

0.7 |

5 |

250 |

|

|

TQFN3x3-20 |

COT |

2 |

1 |

40 |

1.8 |

25 |

REFIN Setting |

5 |

700 |

|

|

QFN 3x3 20 TQFN 3x3 16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5 1.35|1.2 0.5 |

5 |

800 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

180 |

|

◀ 上一篇:两相电压模式和固定频率降压控制器CXSD62103从100kHz到800kHz的可编程脉宽调制开关频率无损耗低边MOSFET Ron电流传感

下一篇▶:电荷泵CXSD62105笔记本电脑的系统电源脉宽调制控制器集成了双降压恒时同步的脉宽调制控制器