CXSD6279B提供输出负载变化的良好调节。内部0.8V温度-补偿参考电压的设计满足

低输出电压应用。它包括一个200kHz的自由运行三角波振荡器,可从70kHz调整到800kHz。上电复位(POR)电路监控VCC、EN和OCSET启动或关闭集成电路的输入电压。过电流保护(OCP)使用上部的电压降监测输出电流MOSFET的RDS(开),消除了对电流传感电阻的需要。欠压保护(UVP)监测FB引脚的电压短路保护

-

[ 产品资料下载 ]

目录

1.产品概述 2.产品特点

3.应用范围 4.下载产品资料PDF文档

5.产品封装图 6.电路原理图

7.功能概述 8.相关产品

一,产品概述(General Description)

The CXSD6279B is a voltage mode and synchronous PWM controller

which drives dual N-Channel MOSFETs. It inte-grates the control, monitoring,

and protection functions into a single package, provides one controlled power

outputs with under-voltage and over-current protection.CXSD6279B provides

excellent regulation for output load variation. An internal 0.8V temperature-

compensated reference voltage is designed to meet the requirement of

low output voltage applications. It includes a 200kHz free-running

triangle-wave oscillator that is adjustable from 70kHz to 800kHz.

The power-on-reset (POR) circuit monitors the VCC, EN,and OCSET

input voltage to start-up or shutdown the IC.The over-current protection (OCP)

monitors the output current by using the voltage drop across the upper

MOSFET’s RDS(ON), eliminating the need for a current sens-ing resistor.

The under-voltage protection (UVP) moni-tors the voltage of the FB pin for

short-circuit protection.The over-current protection trip cycle the soft-start

func-tion until the fault events be removed. Under-voltage pro-tection will

shutdown the IC directly.

二.产品特点(Features)

1.)Simple Single-Loop Control Design

Voltage-Mode PWM Control

2.)Fast Transient Response

Full 0–100% Duty Ratio

3.)Excellent Output Voltage Regulation

0.8V Internal Reference

± 1% Over Line Voltage and Temperature

4.)Over Current Fault Monitor

Uses Upper MOSFETs RDS (ON)

5.)Converter Can Source and Sink Current

6.)Small Converter Size

200kHz Free-Running Oscillator

Programmable from 70kHz to 800kHz

7.)14-Lead SOIC Package

8.)Lead Free and Green Devices Available (RoHS Compliant)

三,应用范围 (Applications)

Graphic Cards

DDR Memory Power Supply

DDR Memory Termination Voltage

Low-Voltage Distributed Power Supplies

四.下载产品资料PDF文档

需要详细的PDF规格书请扫一扫微信联系我们,还可以获得免费样品以及技术支持!

五,产品封装图 (Package)

RT (Pin1)

This pin can adjust the switching frequency. Connect a resistor from the RT to the GND for increasing the switch-

OCSET (Pin2)

This pin serves two functions: a shutdown control and the setting of over current-limit threshold. Pulling this pin

below 1.27V will shutdown the controller, forcing the UGATE and LGATE signals to be at 0V.

A resistor (Rocset) connected between this pin and the drain of the high side MOSFET will determine the over

current limit. An internal 200μA current source will flow through this resistor, creating a voltage drop, which

will be com-pared with the voltage across the high side MOSFET.

SS (Pin3)

Connect a capacitor from the pin to the GND to set the soft-start interval of the converter. An internal 10μA

current source charges this capacitor to 5.8V. The SS voltage clamps the error amplifier output, and Figure1

shows the soft-start interval. At t1, the SS voltage reaches the valley of the oscillator’s triangle wave. The

PWM comparator starts to generate a PWM signal to control logic, and the

COMP (Pin4)

This pin is the output of the error amplifier. Add an exter-nal resistor and capacitor network to provide the

loop com- pensation for the PW M converter (see Application Information).

FB (Pin5)

FB pin is the inverter input of the error amplifier and it receives the feedback voltage from an external

resis-tive divider across the output (V OUT). The output voltage is determined by:

EN (Pin6)

Pull the pin higher than 2V to enable the device, and pull the pin lower than 0.8V to shutdown the

device. In shutdown, the SS is discharged and the UGATE and LGATE pins are held low. The EN pin

is the open-collector, and it will not be floating.

GND (Pin7)

Signal ground for the IC.

PHASE (Pin8)

This pin is connected to the source of the high-side MOSFET and is used to monitor the voltage drop

across the high-side MOSFET for over-current protection.

UGATE (Pin9)

Connect the pin to external MOSFET, and provides the gate drive for the upper MOSFET.

BOOT (Pin 10)

This pin provides the supply voltage to the high side MOSFET driver. For driving logic level N-channel

MOSEFT,a bootstrap circuit can be used to create a suitable driver’s supply.

PGND (Pin11)

Power ground for the gate diver. Connect the lower MOSFET source to this pin.

LGATE (Pin 12)

Connect the pin to the external MOSFET, and provides the gate drive signal for the lower MOSFET.

PVCC (Pin13)

This pin provides a supply voltage for the lower gate drive, connect it to the VCC pin in common use.

VCC (Pin14)

This pin provides a supply voltage for the device. When the VCC is above the rising threshold 10.4V,

the device is turned on; conversely, when the VCC is below the falling threshold, the device is turned off.

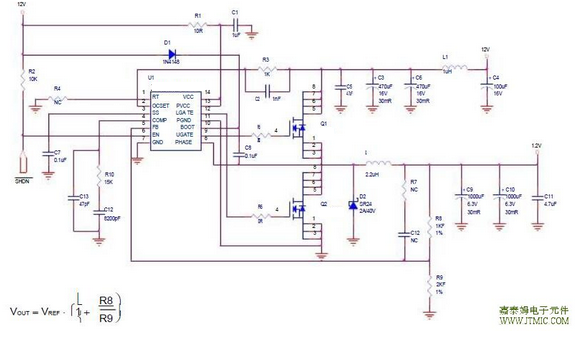

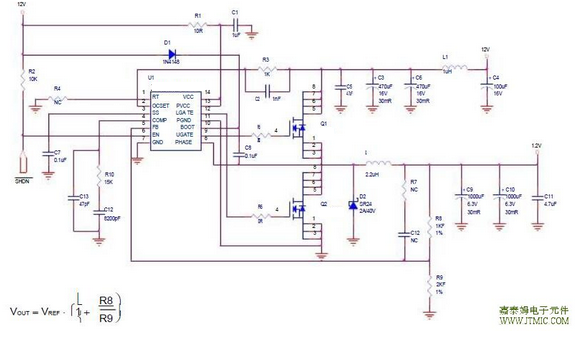

六.电路原理图

七,功能概述

Output Capacitor Selection

The selection of COUT is determined by the required effec-tive series resistance (ESR) and voltage rating

rather than the actual capacitance requirement. Therefore, select highperformance low ESR capacitors

that are intended for switching regulator applications. In some applications,multiple capacitors have to

be paralled to achieve the desired ESR value. If tantalum capacitors are used, makesure they are surge

tested by the manufactures. If in doubt,consult the capacitors manufacturer.

Input Capacitor Selection

The input capacitor is chosen based on the voltage rating and the RMS current rating. For reliable

operation, select the capacitor voltage rating to be at least 1.3 times higher than the maximum input

voltage. The maximum RMS current rating requirement is approximately IOUT/2 , where IOUT is the

load current. During power up, the input capaci-tors have to handle large amount of surge current.

If tanta-lum capacitors are used, make sure they are surge tested by the manufactures. If in doubt,

consult the capacitors manufacturer.For high frequency decoupling, a ceramic capacitor be-tween

0.1μF to 1μF can be connected between the VCC and the ground pin.

Inductor Selection

The inductance of the inductor is determined by the out-put voltage requirement. The larger the

inductance, the lower the inductor’s current ripple. This will translate into lower output ripple voltage.

The ripple current and ripple voltage can be approximated by:

where Fs is the switching frequency of the regulator.There is a tradeoff exists between the inductor’s

ripple current and the regulator load transient response time. A smaller inductor will give the regulator

a faster load tran-sient response at the expense of higher ripple current and vice versa. The maximum

ripple current occurs at the maximum input voltage. A good starting point is to choose the ripple

current to be approximately 30% of the maxi-mum output current.Once the inductance value has

been chosen, select an inductor that is capable of carrying the required peak cur-rent without going

into saturation. In some types of inductors, especially core that is make of ferrite, the ripple

current will increase abruptly when it saturates. This will result in a larger output ripple voltage.

Compensation

The output LC filter introduces a double pole, which con-tributes with –40dB/decade gain slope and

180 degrees phase shift in the control loop. A compensation network between the COMP pin and the

ground should be added. The simplest loop compensation network is shown in

Figure 5.

The output LC filter consists of the output inductor and output capacitors. The transfer function of

the LC filter is given by:

八,相关产品 更多同类产品......

|

Switching Regulator > Buck Controller |

||||||||||

|

Part_No |

Package |

Archi tectu |

Phase |

No.of PWM Output |

Output Current (A) |

Input Voltage (V) |

Reference Voltage (V) |

Bias Voltage (V) |

Quiescent Current (uA) |

|

|

min |

max |

|||||||||

|

SOP-14 QSOP-16 QFN4x4-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

8000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

5000 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP-8 |

VM |

1 |

1 |

20 |

2.2 |

13.2 |

0.8 |

5~12 |

2100 |

|

|

SOP8|TSSOP8 |

VM |

1 |

1 |

5 |

5 |

13.2 |

1.25|0.8 |

5~12 |

3000 |

|

|

SOP-8 |

VM |

1 |

1 |

10 |

3.3 |

5.5 |

0.8 |

5 |

2100 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

2000 |

|

|

TSSOP-24 |QFN5x5-32 |

VM |

1 |

2 |

20 |

5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP14 QSOP16 QFN-16 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

0.9 |

12 |

4000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

30 |

2.2 |

13.2 |

0.6 |

12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

25 |

2.2 |

13.2 |

0.8 |

12 |

5000 |

|

|

LQFP7x7 48 TQFN7x7-48 |

VM |

1 |

6 |

0.015 |

1.4 |

6.5 |

- |

5 |

1800 |

|

|

TSSOP-24P |

VM |

1 |

2 |

20 |

2.97 |

5.5 |

0.8 |

5~12 |

5000 |

|

|

SOP-14 |

VM |

1 |

1 |

10 |

5 |

13.2 |

0.8 |

12 |

3000 |

|

|

SOP-8-P|DIP-8 |

VM |

1 |

1 |

30 |

2.9 |

13.2 |

1.2 |

12 |

3000 |

|

|

SSOP28 QFN4x4-24 |

VM |

1 |

2 |

20 |

5 |

24 |

0.9 |

5 |

1200 |

|

|

SOP-20 |

VM |

1 |

2 |

20 |

2.2 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8|DFN3x3-10 |

VM |

1 |

2 |

- |

- |

- |

- |

5~12 |

550 |

|

|

DIP8|SOP-8 |

VM |

1 |

1 |

1 |

1.2 |

9 |

24 |

5 |

9 ~ 24 |

|

|

SSOP16 QFN4x4-16 TQFN3x3-16 |

VM |

1 |

1 |

25 |

3 |

25 |

0.6 |

5 |

1700 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

3 |

25 |

0.5 |

5 |

350 |

|

|

QFN4x4-24 |

CM |

2 |

1 |

40 |

4.5 |

13.2 |

0.6 |

5~12 |

4000 |

|

|

SOP8P TDFN3x3-10 |

VM |

1 |

1 |

20 |

3 |

13.2 |

0.8 |

5~12 |

2500 |

|

|

SOP8P |

VM |

1 |

1 |

25 |

3 |

13.2 |

0.6|0.8 |

5~12 |

1200 |

|

|

TDFN3x3-10 |

VM |

1 |

1 |

25 |

4 |

13.2 |

0.8 |

5~12 |

2000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

4.5 |

25 |

0.6 |

5~12 |

80 |

|

|

SOP-8P |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.8 |

5~12 |

16000 |

|

|

TQFN3x3-10 |

VM |

1 |

1 |

25 |

4.5 |

13.2 |

0.6 |

5~12 |

2500 |

|

|

CXSD62101|L |

TDFN3x3-10 |

COT |

1 |

1 |

30 |

3 |

25 |

0.8 |

5~12 |

2000 |

|

TQFN3x3-16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

|

CXSD62102A |

TQFN 3x3 16 |

COT |

1 |

1 |

30 |

1.8 |

28 |

0.6 |

5 |

600 |

|

QFN4x4-24 |

VM |

2 |

1 |

50 |

4.5 |

13.2 |

0.6 |

5~12 |

5000 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

TQFN4x4-24 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

|

CXSD62106|A |

TQFN4x4-4 TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

800 |

|

TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3.5x3.5-14 TQFN3x3-16 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

TQFN3x3-16 |

COT |

1 |

2 |

20 |

1.8 |

28 |

0.75 |

5 |

400 |

|

|

QFN3x3-20 TQFN3x3-16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5|0.5 |

5 |

740 |

|

|

TQFN4x4-24 |QFN3x3-20 |

CM |

1 |

2 |

15 |

5 |

28 |

0.5 |

N |

3000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

20 |

1.8 |

28 |

0.5 |

5 |

250 |

|

|

CXSD62113|C |

TQFN3x3-20 |

COT |

1 |

2 |

15 |

6 |

25 |

2 |

N |

550 |

|

CXSD62113E |

TQFN 3x3 20 |

COT |

2 |

2 |

11 |

6 |

25 |

2 |

N |

550 |

|

TQFN3x3-20 |

COT |

2 |

2 |

11 |

5.5 |

25 |

2 |

N |

280 |

|

|

QFN4x4-24 |

VM |

2 |

1 |

60 |

3.1 |

13.2 |

0.85 |

12 |

5000 |

|

|

CXSD62116A|B|C |

SOP-8P |

VM |

1 |

1 |

20 |

2.9 |

13.2 |

0.8 |

12 |

16000 |

|

SOP-20 |

VM |

2 |

2 |

30 |

10 |

13.2 |

1 |

12 |

5000 |

|

|

TDFN3x3-10 |

COT |

1 |

1 |

25 |

1.8 |

28 |

0.7 |

5 |

250 |

|

|

TQFN3x3-20 |

COT |

2 |

1 |

40 |

1.8 |

25 |

REFIN Setting |

5 |

700 |

|

|

QFN 3x3 20 TQFN 3x3 16 |

COT |

1 |

2 |

20 |

3 |

28 |

1.8|1.5 1.35|1.2 0.5 |

5 |

800 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3 20 |

COT |

1 |

2 |

15 |

3 |

28 |

0.75 |

5 |

220 |

|

|

TQFN3x3-20 |

COT |

1 |

2 |

20 |

3 |

28 |

0.75 |

5 |

180 |

|

◀ 上一篇:大功率降压同步DC/DC控制器CXSD6278驱动外部N通道mosfet的300kHz恒频电压模式同步开关控制器。

下一篇▶:CXSD6280两个同步降压型脉宽调制控制器高精度内部参考电压的线性控制器PWM控制器同步buck拓扑中的两个N沟道mosfet